Sumisura

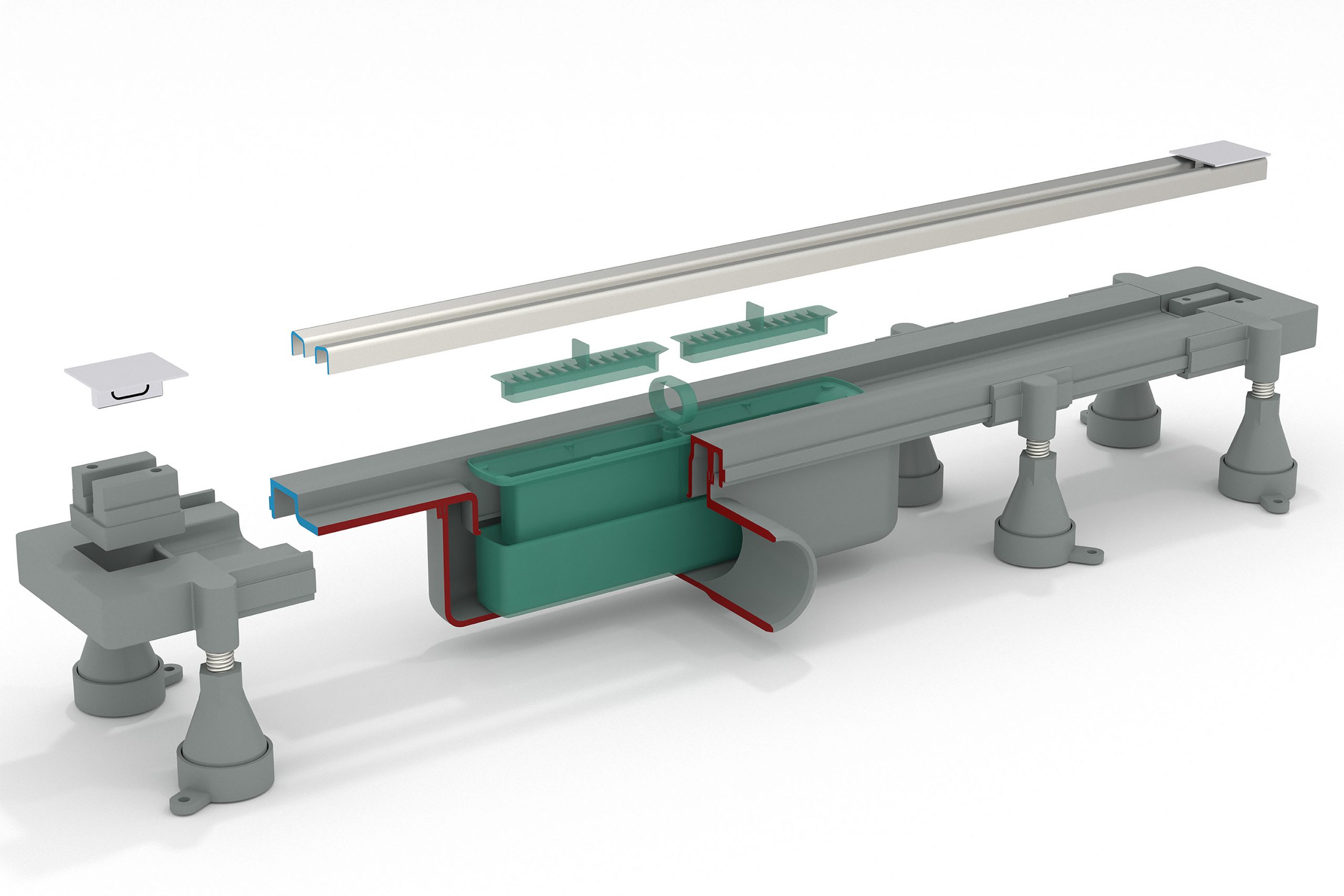

Sumisura is an adjustable and modular shower channel. It comes with unsoldered end caps, allowing for easy cutting to the desired length using the provided template (which also ensures proper cutting of the stainless steel grid). After adjusting the length, the channel is completed by attaching the end caps with TCF glue (included in the standard package), which seals the channel and supports the grid above.

![-983.2018 [22.08.01-B]](https://www.omptea.eu/wp-content/uploads/2024/05/983.2018-22.08.01-B.jpg)

The modular design of Sumisura allows for the end caps to be replaced with joints (available separately), enabling the connection of multiple channels in both linear and angled configurations.

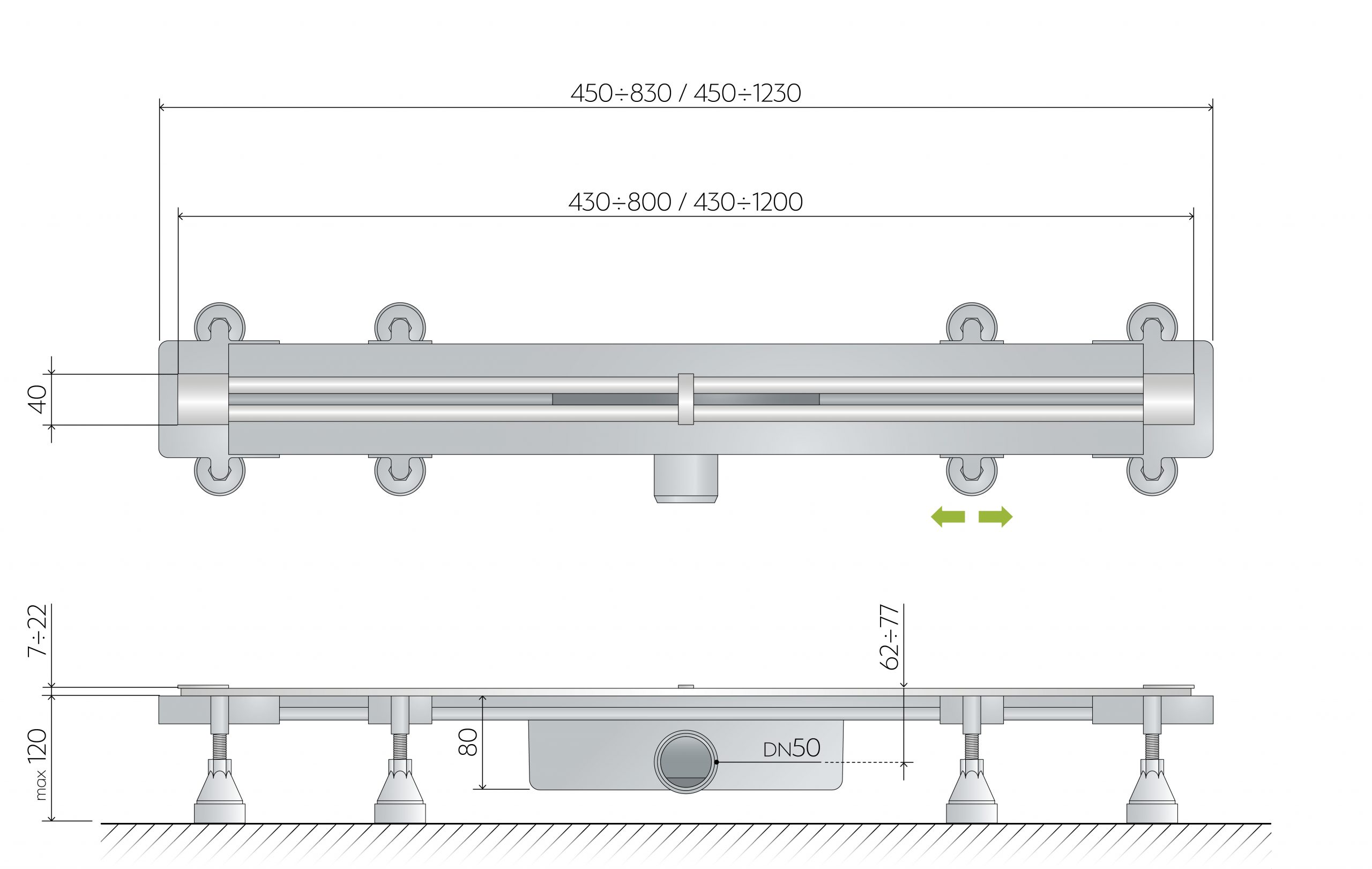

Sumisura is available in the following lengths:

- L.max 800 mm

- L.max 1.200 mm

The trap is made of ABS, while the exposed parts of the grid are crafted from AISI 316 stainless steel with square chrome-plated brass end caps. This high-quality steel is particularly resistant to wear and the corrosive effects of chemicals or saltwater.

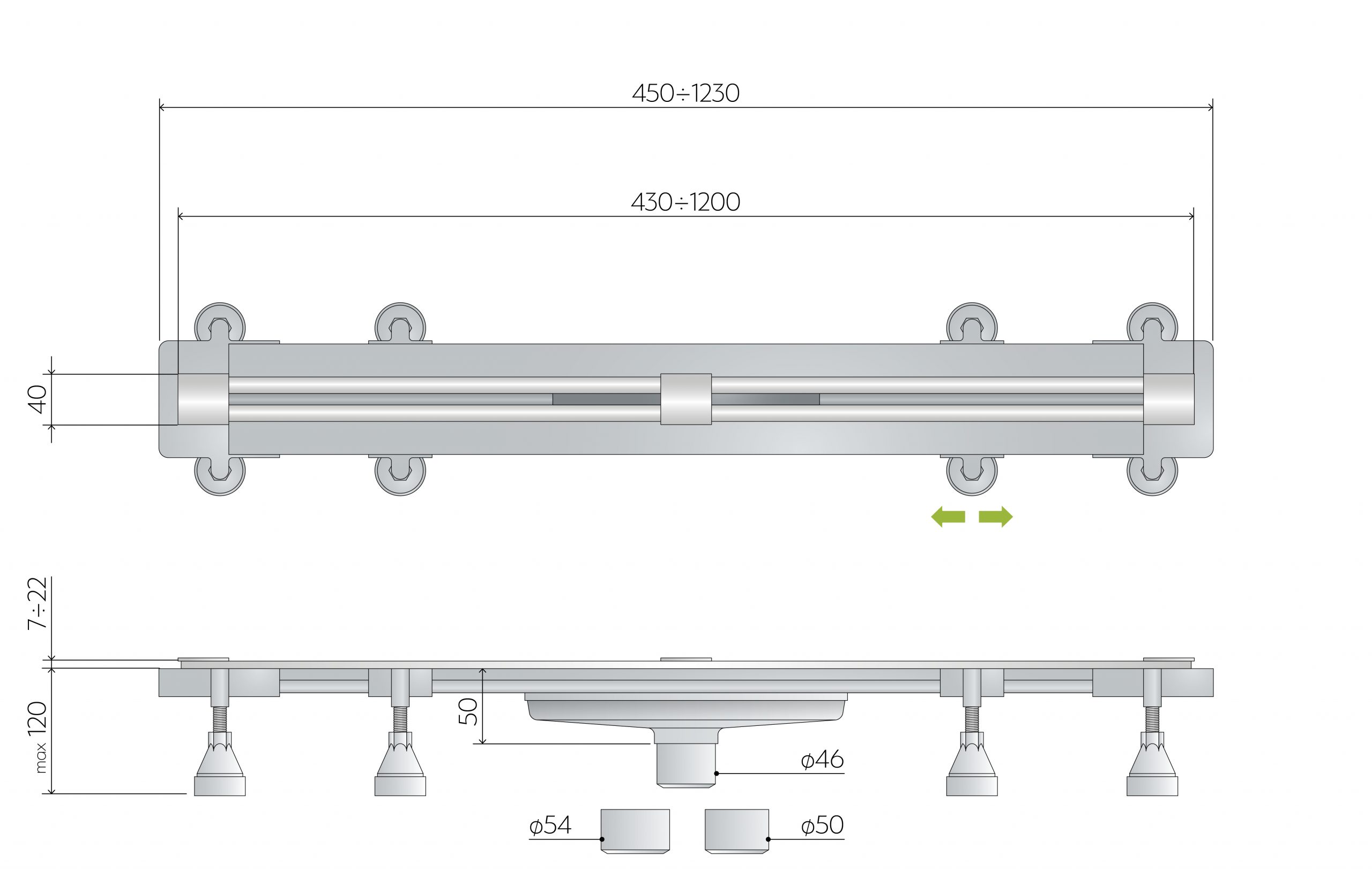

The standard version includes a trap with a horizontal DN50 outlet and a traditional hydraulic siphon (35mm siphon). There is also an option with a dry siphon, where siphoning is achieved through the closure of a mobile partition rather than storing water inside the trap. For the version with a vertical ø46/50/54 outlet, no siphon system is included.

![-983.2018 [23.05.06]](https://www.omptea.eu/wp-content/uploads/2024/05/983.2018-23.05.06-scaled.jpg)

As for the other shower channels of OMP TEA floor range, also Sumisura is supplied with kit for the drain perimeter waterproofing that secures the contact area between the shower channel and the screed and serves as a basis for the completion of the insulation layer to be made by cement glues waterproofing or technical fabrics.

For more information about thin bed waterproofing and the dedicated products of OMP TEA , we invite to visit the installation page.

In addition to the waterproofing kit in the package you can also find:

- supports to ease the installation and allow a handy adjustment adapting to any roughness of the surface

- everything you need for siphoning (vertical outlet version excluded)

- cover grid

- instruction sheet

Available range

Dimensions and encumbrances

With horizontal DN50 outlet:

- tile thickness from a minimum of 7 mm to a maximum of 22 mm

- minimun installation depth 80 mm

With vertical ø46/50/54 outlet:

- tile thickness from a minimum of 7 mm to a maximum of 22 mm

- minimun installation depth 50 mm

Main features

- length adjustment from min. 430 to max. 1200 mm

- AISI 316 stainless steel grid adjustable in height from 7 to 22 mm

- thin-bed perimeter waterproofing

- removable trap for cleaning

- adjustable supports to ease the installation

- dry-spot: drainage point for the water filtered through the flooring

- lateral DN50 ABS outlet

- tile thickness 7-22 mm

- minimun installation depth H. 80 mm

- 35 mm siphon (with hydraulic siphon)

- flow rate 36 l/min

Horizontal outlet version with dry trap

![-983.2718 [21.04.22]](https://www.omptea.eu/wp-content/uploads/2024/06/983.2718-21.04.22-scaled.jpg)

Vertical outlet version without trap

![-982.4018 [23.05.26]](https://www.omptea.eu/wp-content/uploads/2024/06/982.4018-23.05.26-scaled.jpg)

Box contents

- 1 x height-adjustable AISI 316 stainless steel and brass grid

- 1 x Trapped ABS shower channel

- 2 x end caps with leveling supports (feet)

- 2 x central and sliding leveling supports (4 for size 1.200)

- 1 x TCF glue for soldering the end caps

- 1 x Removable trap and hair stop grids for cleaning (vertical outlet version with only stainless steel hairstop grid)

- 1 x Thin-bed perimeter waterproofing

- 1 x template for proper cutting of the channel and grid

- 1 x instruction sheet

![-983.2018 [24.05.29]](https://www.omptea.eu/wp-content/uploads/2024/05/983.2018-24.05.29-scaled.jpg)

Installation guide

Joints

Special fittings can be added to the Sumisura channels, allowing the assembly of multiple channels to extend the drain length or increase water flow.

They are available for both linear and angled connections. Instruction sheets for the relevant joints are available at the end of the page.

Linear joint

Art. 987.000.0 + 987.001.0

A continuous linear joint (without interruptions between the grids) of multiple channels can be achieved by adding a linear joint art. 987.000.0 (nr. 2 in the image) every two channels.

When using this joint, the end caps already supplied with the product, should not be used; instead, the two channels should be soldered to the joint itself.

The brass end caps of the grille are also not needed in this case, and it is recommended to combine them with the kit 987.001.0 (nr. 1 in the image), which maintains the aesthetic consistency of the joint with a single 40×40 mm chrome-plated piece, while allowing easier removal of the single 800 or 1200 mm grid instead of the entire assembled unit.

A seamless linear connection of multiple channels can be achieved by using the linear joint art. 987.000.0 (item 2 in the image) for every two channels. When utilizing this joint, the end caps supplied with the channels should not be used; instead, the channels should be soldered directly to the joint. The brass end caps of the grid are also unnecessary in this setup. It is recommended to use the kit 987.001.0 (item 1 in the image), which maintains the aesthetic continuity with a single 40×40 mm chrome-plated piece, allowing for easier removal of individual 800 or 1200 mm grids instead of the entire assembled unit.

![-987.0000 [24.05.30]](https://www.omptea.eu/wp-content/uploads/2024/06/987.0000-24.05.30-scaled.jpg)

Angled joint

Art. 987.004.0

For the angled joint, the brass grid end caps remain separate, so the end caps supplied with the channels should be used, and no additional kit is required. However, the channel end caps are removed and must be soldered directly onto the angled joint art. 987.004.0 (item 3 in the image).

![-987.0040 [24.05.30]](https://www.omptea.eu/wp-content/uploads/2024/06/987.0040-24.05.30-scaled.jpg)

Other finishing available

PVD Gun Metal

Art. 983.201.8.N L.max 800 mm

Art. 983.401.8.N L.max 800 mm

![-987.2010N [24.06.03]](https://www.omptea.eu/wp-content/uploads/2024/06/987.2010N-24.06.03.jpg)

PVD Gold

Art. 983.201.8.3 L.max 800 mm

Art. 983.401.8.3 L.max 800 mm

![-987.20103 [24.06.03]](https://www.omptea.eu/wp-content/uploads/2024/06/987.20103-24.06.03.jpg)

PVD Copper

Art. 983.201.8.3 L.max 800 mm

Art. 983.401.8.3 L.max 800 mm

![-987.2010Q [24.06.03]](https://www.omptea.eu/wp-content/uploads/2024/06/987.2010Q-24.06.03.jpg)

Instruction sheets

1. horizontal DN50 outlet version with water trap

for art. 983.201.8 – 983.401.8

2. horizontal DN50 outlet version with dry trap

for art. 983.201.8 – 983.401.8

3. vertical ø46/50/54 outlet version without trap

for art. 982.401.8

4. Linear joint

for art. 987.000.0

5. Angled joint

for art. 987.004.0

6. Chrome-plated brass cover to keep separate the single grid in linear joint, to be combined with 987.000.0

for art. 987.001.0